DON’T WASTE THE WASTE, USE DDI ENERGY RECOVERY

DDI HEAT EXCHANGER FLOW EXPLAINED

Get the Questionnaires for this video

Direct Sludge to Sludge Heat Recovery in Wastewater Treatmnent / Environmental Technology NewsHour 6

DDI full presentation by Erwin February 1 2018 (30 minute training)

Erwin Schwartz at DRAGON DEN for DDI Heat Exchangers Inc

George Ross interviewed by Erwin Schwartz of DDI Heat Exchangers Inc

ENERGY RECOVERY & Heating & Cooling from GREY WATER and WWTP and CITY SEWAGE PIPES

A practical solution to save Wasted energy.

Return On Investment possible within 1 year.

INNOVATIVE APPROACH IN HEAT RECOVERY

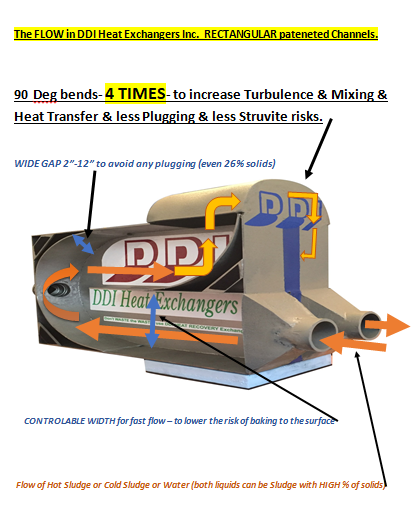

USING DDI Patented “Rectangular, Square, Cube” R, Very LARGE GAPS

METHODOLOGY

Failed attempts to modify existing Spiral, and Shell and Tube Heat Exchangers for Heat Recovery application due to PLUGGING or BAKING, led to the development of new breed of DDI “Rectangular, Square, Cube” R Large Gap Heat Exchangers that provide worry free, NON PLUG operation, despite presence of stringy and sticky materials in municipal sludge or Grey Water flow.

The Energy Recover Solutions are Patented Technology with Major Benefits in different markets:

1- In Waste Water Treatment Plants,

ROI is less than 1 year.

Due to DDI’s DIRECT-Sludge-to-Sludge Heat Recovery from the Hot Wasted Digested Sludge, to the Cold Raw Sludge. Low risk of plugging due to the very large gaps, and low risk of baking to the surface due to the controlled fast flow of the sludge.

2- In Wasted GREY / BLACK Water,

ROI is 1-3 years depends on buildings size.

Save 10-30% on building’s or Hotel’s heating costs.

DUE to DDI’s Rectangular channels which allow complying with the law requirement of DOUBLE Walls efficiently.

3- In Recovering Energy DIRECTLY from the CITY SEWAGE which flows below the building,

ROI is 1-2 years depends on buildings size.

Save 20-30% on building’s heating and cooling costs.

DUE to DDI’s Rectangular channels which allows for Direct flow of the City Sewage to the DDI Heat exchanger.

Without holding tanks or screens or macerators costs.

4- In “Yes Pasteurization” tm

ROI is about 1 year, depends on the WWTP size.

Due to DDI’s DIRECT-Sludge-to-Sludge Heat Recovery from the Hot Wasted Digested Sludge, to the Cold Raw Sludge. Low risk of plugging due to the large gaps, and low risk of baking to the surface due to the controlled fast flow of the sludge.

All systems are:

- Easy to install.

- Nearly maintenance free.

- Virtually clog free, no more down time from clogging.

- Savings on your energy cost

- Green promotion with new technology utilization.

New Feature

Comparing DDI “Rectangular, Square, Cube” tm Heat Recovery to competition

Since DDI’s Heat Recovery System has a Minimum Gap of 3″ on both sides (to avoid blockage) it makes no difference which side has Water or Sludge, or even both sides could have Sludge (for Heat Recovery).

We achieved our NON-PLUG design (compared to the Spiral design) via large GAPS, NO OBSTACLES and ROUND CURVES.

DDI has achieved the possibility of having THE SAME FLOW in both sides (for Heat Recovery), compared to Tube and Shell exchangers which cannot do it (see the SURFACE Heat Transfer area and FLOW area Comparisons).

DDI’s overall size is SMALLER then the Tube and Shell and does not require Grinders or Macerators or Screens (saves 200,000$ in 10 years) as the Spiral design does.

We have had many Engineers working for many years to come up with this design and TESTED it in real life with MANY working units.

Our Mission

To provide high quality Heat Exchangers with our unique, efficient, non-pluggable design.

Our Heat Exchanger is the ONLY efficient heat-recovery exchanger available.

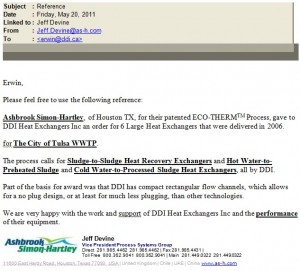

Company Profile

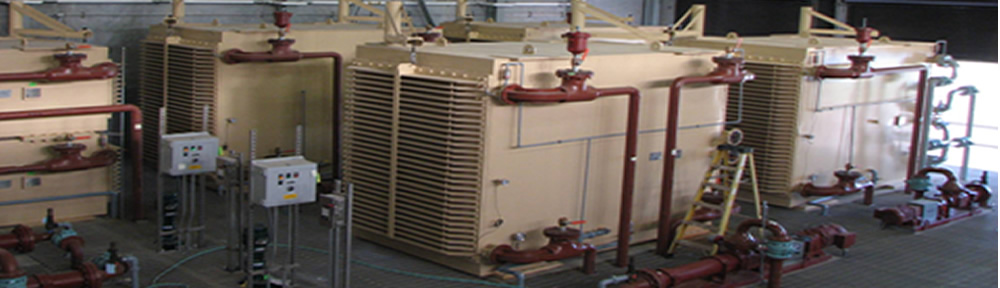

DDI was founded in 1980 and has been providing quality service and reliable solutions ever since. DDI is a well established Canadian company experienced in the design and manufacturing of plate type heat exchangers specifically suitable for applications in heat recovery from liquid waste materials containing large size solids such as municipal sludges and many other processes.

Contact Information

Telephone

514-696-7961

FAX

514-696-8344

Mailing address

305 Baffin, Dollard-Des-Ormeaux (Montreal), Quebec Canada H9A3G4

U.S. Address

(Please send mail to the mailing address above)

Electronic mail

General Information: Contact Us

.

.

Please help us to improve and promote the new

GREY WATER “Energy Recovery Solution”.

By emailing us your comments. We thank you for your support.